The term "surface finishing" refers to a wide variety of distinct industrial processes that are used to modify the surface of a manufactured item, product, or component in order to achieve or improve a property or characteristic. These processes are carried out in order to achieve or improve a property or characteristic. The culmination of all of these different processes is referred to as surface finishing, and it is referred to by that term. Depending on what it is that is being finished, a surface can be finished in such a way that it achieves or improves a wide variety of properties and characteristics, and this can depend on what it is being finished. The terms "surface finishing" and "surface treatment" are interchangeable and should be used accordingly. The surface finish of a component is one of the most important factors that determines how the component will look, how it will feel, and how well it will function. The other two factors are the material and the manufacturing process. The surface can have a variety of finishes, ranging from matt to highly polished. It is essential to have Surface Finish Services in order to design a product that is successful, and it is also essential to have a good surface finish in order to design a product that is successful.

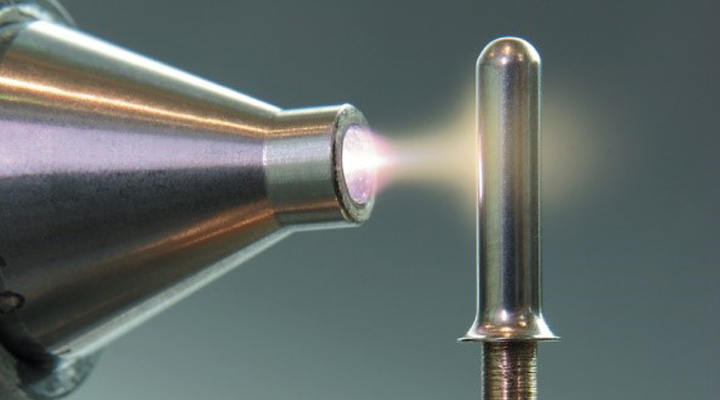

#1 The oxidation that takes place as a direct consequence of an electrolysis process being applied to plasma.

The Plasma Electrolytic Oxidation (PEO) process is an electrochemical method that generates a plasma discharge at the metal-electrolyte interface. This plasma discharge is produced by applying a high voltage to the system. Plasma discharges take place whenever the applied voltage is greater than the breakdown value, which is typically situated somewhere in the range of a few hundred to a few thousand volts. These values determine the minimum and maximum voltages at which a breakdown occurs. Plasma discharges are also capable of happening when the voltage is lower than the value at which they break down. In the event that the breakdown value is exceeded, there is also the possibility of plasma discharges occurring. The processing of magnesium-titanium-aluminum alloys in the manner described by this method is the most illustrative illustration of this, as it exemplifies the point in the clearest possible manner.

Using a brush, buff the surface to a shine that is almost reflective and move on to step 2.

It is common practice to also refer to brushed polish or dull polish as a satin finish or dull finish. This is because brushed polish and dull polish have very similar appearances. This is due to the fact that brushed polish and dull polish have extremely comparable visual qualities. This is due to the fact that brushed polish and dull polish have extremely similar qualities to one another when viewed visually. Additionally, other kinds of metals, like titanium and copper, are brushed quite frequently as well. Both brass and bronze are different kinds of metals, but they are both examples of brass. The use of brushed finishes is becoming a trend that is increasingly popular in a wide variety of product categories, such as whiteware, small appliances, architectural design, and automotive design, to name just a few of these areas of application. This is just to name a few of these areas of application. The surface roughness is typically measured in the range of 0 to 1, and it corresponds to the degree to which the finish has been brushed.

#3 Vitreous enamel

Vitreous enamel is a type of enamel that is produced by fusing powdered glass to a substrate at temperatures ranging from 1,380 to 1,560 degrees Fahrenheit (750 to 850 degrees Celsius). This process takes place at temperatures ranging from 750 to 850 degrees Celsius. Temperatures ranging from 1,380 to 1,560 degrees Celsius are necessary for the completion of this process. The end result of this process will be the formation of a surface that is extremely resistant to wear and tear and has the potential to last for an extremely long time. On the other hand, enamels are utilized on metals the vast majority of the time; however, enamels can also be utilized on surfaces that are composed of glass and ceramics so long as the necessary conditions are met. Enamels can also be used for a wide variety of other applications, which is another perk of this material. Because of this, a smooth coating will be produced on the surface of the object, as a result of the enamel bonding to the surface while the process is being carried out.

In the fourth explosion, beads were used as projectiles instead of traditional explosives. In order to achieve this effect, the utilization of glass beads is required. The high-pressure ejection of small glass beads is one method that may be used in this process to accomplish either of those goals. Another method that may be used is the high-pressure ejection of larger glass beads. Depending on the outcome that you want the process to have, you can either clean or polish a surface using this method. The choice is yours. This can be done by directing a stream of very small glass beads toward the surface of the material that needs to be cleaned. Bead blasting is one example of a process that can be used to achieve this kind of Surface Finish Services on a material. There are also other methods that can be used.

#5 Sandblasting

Sandblasting, which is also known as abrasive blasting, is a method of surface finishing that involves spraying abrasive particles against a surface at a high rate of pressure using a powered machine, which typically also includes an air compressor in addition to a sandblasting machine. Sandblasting is also sometimes referred to as abrasive blasting. Another name that is sometimes used to refer to the process is abrasive blasting. Sandblasting is also known by the name abrasive blasting, which is yet another name. Sandblasting is a process that gets its name from the fact that it involves propelling sand particles at the surface in order to remove material from the surface. The process is known by this name because it removes material from the surface by using sand. Sand particles, when they collide with the surface, produce a texture that is more even and smoother. This is because sand particles are made up of very small particles. This is because individual sand grains are made up of incredibly minute particles, which accounts for why this is the case.